Non woven fabrics are a new kind of textile made from fibers, mostly from polypropylene. This material is made by binding fibers together. It’s interesting to know if these fabrics can handle moisture.

In this article, we’ll look into the properties of non woven fabric. We’ll see if they can absorb moisture. Knowing this is key for industries that need to manage moisture well.

Key Takeaways

- Non woven fabrics are primarily made from polypropylene.

- They display unique characteristics, including softness and air permeability.

- Hydrophilic non woven fabrics can absorb and retain water effectively.

- These fabrics are increasingly used in medical and hygiene products.

- Technological advancements are driving the growth of the non woven fabric market.

- Their use spans various industries, including healthcare, agriculture, and automotive.

What Are Non-Woven Fabrics?

Non-woven fabrics are made by bonding fibers together. They use methods like mechanical, thermal, and chemical processes. This is different from traditional weaving, where fibers are woven together.

These fabrics have fibers arranged randomly. This makes them durable, flexible, and versatile. They have unique characteristics of non woven fabrics.

Definition and Characteristics

Non-woven materials are light and absorbent. They are good for many uses. They can weigh between 10 to 150 gsm and be up to 1600 mm wide.

This makes them useful in many industries. They are used in medical products and agriculture. Over 100 companies worldwide use them, showing their demand.

Comparison with Woven Fabrics

Woven fabrics are made by weaving threads together. They are strong and look good. But, non-woven fabrics are better at absorbing and are cheaper.

They are great for medical and hygiene products. New production methods have made them even better. They are now used in cars and buildings too.

Understanding Moisture Absorption

Understanding moisture absorption definition means knowing how well materials soak up and hold moisture. This is key in places like healthcare and hygiene. Each fabric absorbs moisture differently, based on its makeup and structure.

What is Moisture Absorption?

Moisture absorption shows how well a fabric can take in water. It’s vital for figuring out how fabrics handle moisture in real life. For example, cotton can hold up to 27 times its weight in water, showing it’s very good at absorbing moisture.

On the other hand, synthetic fibers are used in some athletic clothes because wet cotton can be uncomfortable. Knowing how fabrics absorb moisture helps pick the right materials for certain jobs.

Different Levels of Moisture Absorption

Fabrics vary a lot in how they manage moisture. For example, cotton, synthetic fabrics, and non-woven types absorb moisture differently. Here are some interesting facts:

- Needle punch nonwoven fabrics range from 100gsm to 1,000gsm, with varying moisture absorption capabilities.

- Nollapelli’s bedding products are two times more breathable than cotton sheets, showing better moisture management.

- Airlaid fabrics can have up to 60% SAF™ Fibre content, making them more absorbent.

These differences show how varied fabric performance can be. It’s crucial for makers to understand this when creating products for specific markets.

Does Non Woven Fabric Absorb Moisture

Understanding how non-woven fabrics handle moisture is key. There are many types, each with its own moisture management abilities. These abilities often guide their use in different applications.

Types of Non-Woven Fabrics

Non-woven fabrics come from various production methods and uses. Here are some common ones:

- Spunlace nonwovens

- Needle-punched nonwovens

- Hot air nonwovens

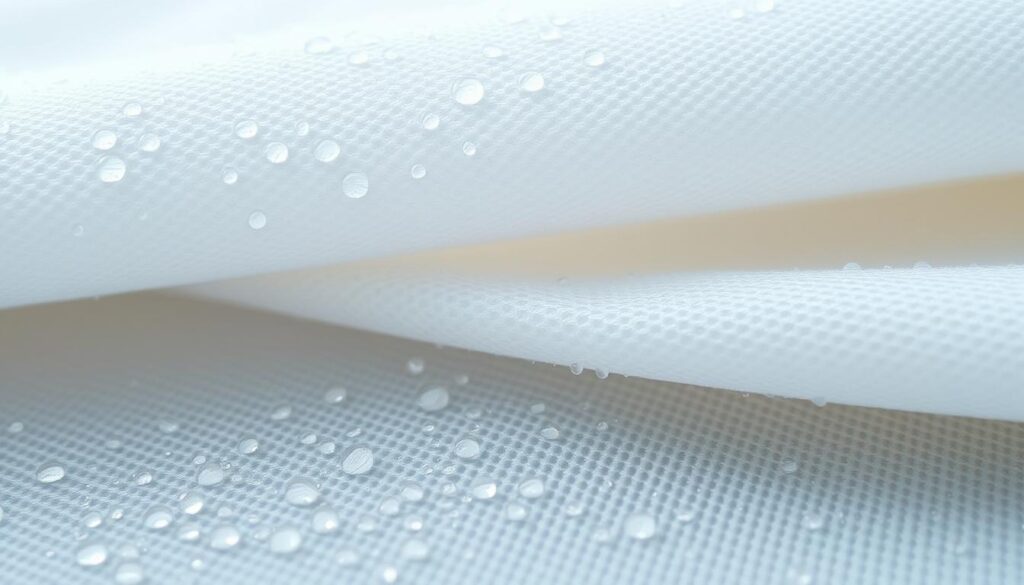

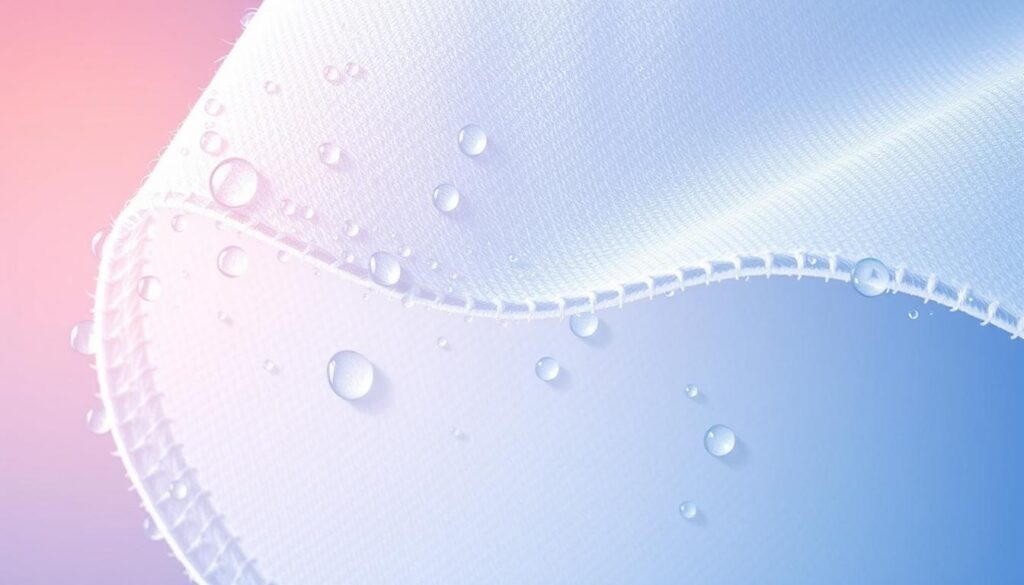

Hydrophilic vs Hydrophobic Properties

Knowing the difference between hydrophilic and hydrophobic fabrics is crucial. Hydrophilic fabrics draw in and soak up moisture well. They’re great for medical uses, keeping things clean and sterile.

On the other hand, hydrophobic fabrics push moisture away. They’re perfect for keeping things dry, like in waterproof clothes. This makes them ideal for wet or humid places.

The choice between these fabrics can make a big difference. It affects how well a product works and how comfortable it is. Picking the right fabric is a big part of making a product successful.

Properties of Non-Woven Fabrics That Influence Absorption

Knowing about non woven fabric properties is key to their moisture management success. Their durability and flexibility affect how well they absorb moisture. The web-like structure of non-woven fabrics makes them good at holding onto moisture. This part explores the main traits that make non woven fabrics absorbent.

Durability and Flexibility

The durability and flexibility of fabrics are crucial for their performance. Non-woven fabrics are made to handle stress without losing shape. They are very resistant to wear and tear, perfect for long-lasting moisture management. Their flexibility also lets them fit well on different surfaces, making them very useful.

Absorbency Features

The absorbency of non woven fabrics is boosted by their softness and air permeability. Research shows that better air flow means better moisture management. These fabrics can hold a lot of moisture because of their porous nature. This makes them great for many uses, from medical to hygiene products. Knowing these traits helps both buyers and makers choose the right non-woven fabrics.

| Property | Impact on Absorbency |

|---|---|

| Durability | Enhances longevity, reducing wear and tear |

| Flexibility | Allows better conformity to surfaces, improving seal integrity |

| Air Permeability | Facilitates moisture release, preventing dampness |

| Softness | Increases comfort and enhances skin contact applications |

Applications of Non-Woven Fabrics in Moisture Management

Non-woven fabrics are key in many industries, especially in managing moisture. They are perfect for places where controlling moisture is crucial. This is especially true in the medical and hygiene fields.

Medical Textiles

In medicine, non-woven fabrics are vital for keeping patients safe. They are used in surgical masks, wound dressings, and disposable gowns. These materials help control infections and keep the environment clean.

Their ability to absorb moisture is a big plus. It helps keep the area around patients clean and safe during treatments.

Hygiene Products

Non-woven fabrics have made hygiene products better. They are used in adult diapers and sanitary pads. These fabrics soak up moisture well, keeping users dry and comfortable.

This comfort and dryness are key to good hygiene. It’s why these products are so popular.

Hydrophilic Non-Woven Fabrics: An In-Depth Look

Hydrophilic non-woven fabrics are key in many industries because they soak up moisture well. Knowing how they’re made and their uses shows their importance in our lives.

Manufacturing Process

To make hydrophilic non-woven fabrics, special agents are added to the fibers. These agents boost the fabric’s ability to absorb moisture. Methods like needle punching, spunbonding, and hydroentangling are used to get this effect.

The result is a fabric that keeps its shape and lasts long. It also manages moisture well.

Common Uses in Daily Life

Hydrophilic non-woven fabrics have many uses in our daily lives. They are used in:

- Medical Textiles: In wound dressings and surgical covers for their absorbency and cleanliness.

- Hygiene Products: In diapers and feminine hygiene products for comfort and moisture control.

- Cleaning Products: In cleaning wipes for homes and industries because they hold liquids well.

- Protective Clothing: In disposable gowns and protective gear for their moisture absorbency.

Comparative Analysis: Non-Woven Fabrics vs Other Materials

Looking at non woven fabrics and other materials, we see how absorbency and cost matter. Non woven fabrics often beat woven ones in handling moisture. Their special structure helps them hold and spread water fast.

Performance in Absorbency

Non woven fabrics are great at soaking up moisture. Their fibers are stuck together, making it easier for them to grab and hold water. Woven fabrics, though airy, don’t soak up water as well. This makes non woven fabrics perfect for things like surgical gowns and wipes.

Cost-Effectiveness

Non woven fabrics are also a smart choice for many industries. They need less to make than woven fabrics, saving on costs. This means businesses can make more with less money spent. Plus, non woven fabrics are used in many places, showing they’re a good deal.

| Material Type | Absorbency | Cost-Effectiveness |

|---|---|---|

| Non-Woven Fabrics | High moisture retention; fast drying | Lower manufacturing costs; versatile applications |

| Woven Fabrics | Moderate moisture retention; breathable | Higher production costs; limited adaptability |

Challenges and Limitations of Non-Woven Fabrics

Non-woven fabrics have many benefits but also face challenges. One big issue is managing moisture. These fabrics can hold onto moisture, which can cause problems. This can lead to discomfort or inefficiency in certain situations.

Potential Issues in Moisture Management

The structure of non-woven fabrics can cause moisture to build up. This can make them feel damp or even smell bad. For products like medical textiles and hygiene items, managing moisture is key.

Different types of non-woven fabrics, like spunbond or meltblown, have their own issues. Understanding these challenges is important for their performance.

Environmental Concerns

Non-woven fabrics also have environmental concerns. They are often made from synthetic fibers, which are not biodegradable. This raises worries about how to dispose of them.

As people become more aware of sustainability, there’s a push to make these products better. Finding ways to reduce their environmental impact is a big challenge. It’s important to find a balance between their performance and being eco-friendly.

Future Trends in Non-Woven Fabric Technology

The non-woven fabric industry is set for big changes soon. It’s key to know about these trends to make fabrics better and greener. New materials are being made to fix old textile problems and offer eco-friendly choices.

Innovations in Absorbency

People want fabrics that do more, like absorb better. New ideas are popping up, like:

- Biodegradable Materials: Kaneka Corp has made eco-friendly fabrics that manage moisture well, perfect for sports clothes.

- Quick-Drying Textiles: Zhejiang Sailisi Environmental Protection Technology has created fabrics that soak up moisture fast and dry quickly.

- Enhanced Strength: Quanzhou Haitian Material Technology and Donghua University are working on strong, biodegradable fabrics for many uses.

- Industry Partnerships: The “Ecovance” partnership aims to change how sustainable textiles are made with new fiber technologies.

Sustainable Manufacturing Practices

Making non-woven fabrics in a green way is now a must. Important steps include:

- Using bio-based materials to cut down on petroleum-based fibers and lessen environmental harm.

- Creating safe, degradable flame retardants that meet green standards.

- Working together between startups, big companies, and research groups to bring out new green tech.

The non-woven fabrics market is expected to grow a lot. It’s set to jump from USD 31.1 billion in 2021 to USD 57.18 billion by 2030. This growth shows a big interest in green, functional, and absorbent fabrics. As the industry meets new needs, these new ideas and methods will guide the future of making textiles.

Conclusion

Non woven fabrics have many properties that make them great at absorbing moisture. This is why they are perfect for many uses, like medical textiles and hygiene products. Their strength and flexibility, thanks to materials like polypropylene, help them work well in different situations.

Studies show how important it is to know about these fabrics’ special features. As new uses are found, the need for certain types of non woven fabrics grows. This helps them meet our needs while staying functional and green, which is key today.

Non woven fabrics are used in many ways, from improving clothes to adding insulation. Looking ahead, these fabrics will keep getting better. They will meet our needs for better performance and being eco-friendly in many areas.

FAQ

Does non woven fabric absorb moisture effectively?

Yes, non woven fabrics can absorb moisture well. This is especially true for hydrophilic non woven fabrics. They are made to attract and hold moisture. This makes them great for healthcare and hygiene needs.

What are non-woven fabrics?

Non-woven fabrics are made by binding fibers together. This is done through mechanical, thermal, or chemical methods. They are flexible and durable, making them useful for many things.

How does moisture absorption differ between non-woven and woven fabrics?

Non-woven fabrics absorb moisture better than woven ones. Their special construction and materials help them handle moisture well. This is important in many applications.

What types of non-woven fabrics are available?

There are many types of non-woven fabrics. Some absorb moisture, while others repel it. Choosing the right one is important for specific uses.

What properties of non-woven fabrics affect moisture absorption?

The key properties include durability, flexibility, and air permeability. These help the fabric manage moisture well.

How are non-woven fabrics used in the medical field?

In medicine, non-woven fabrics are crucial. They are used in masks, dressings, and gowns. Their ability to absorb moisture and act as barriers is vital for safety.

What are common applications of hydrophilic non-woven fabrics?

Hydrophilic non-woven fabrics are used in personal care items. This includes adult diapers and sanitary pads. They are good at absorbing moisture and keeping users comfortable.

How do non-woven fabrics compare to other materials in absorbency?

Non-woven fabrics are better at absorbing moisture than woven ones. They are also more cost-effective for manufacturers.

What challenges do non-woven fabrics face regarding moisture management?

Challenges include issues with moisture retention and environmental concerns. Some non-woven materials are not biodegradable, which can be a problem.

What future trends are emerging in non-woven fabric technology?

Future trends include better absorbency and sustainability. There’s a focus on bio-based non-woven fabrics. These are more eco-friendly and still perform well.